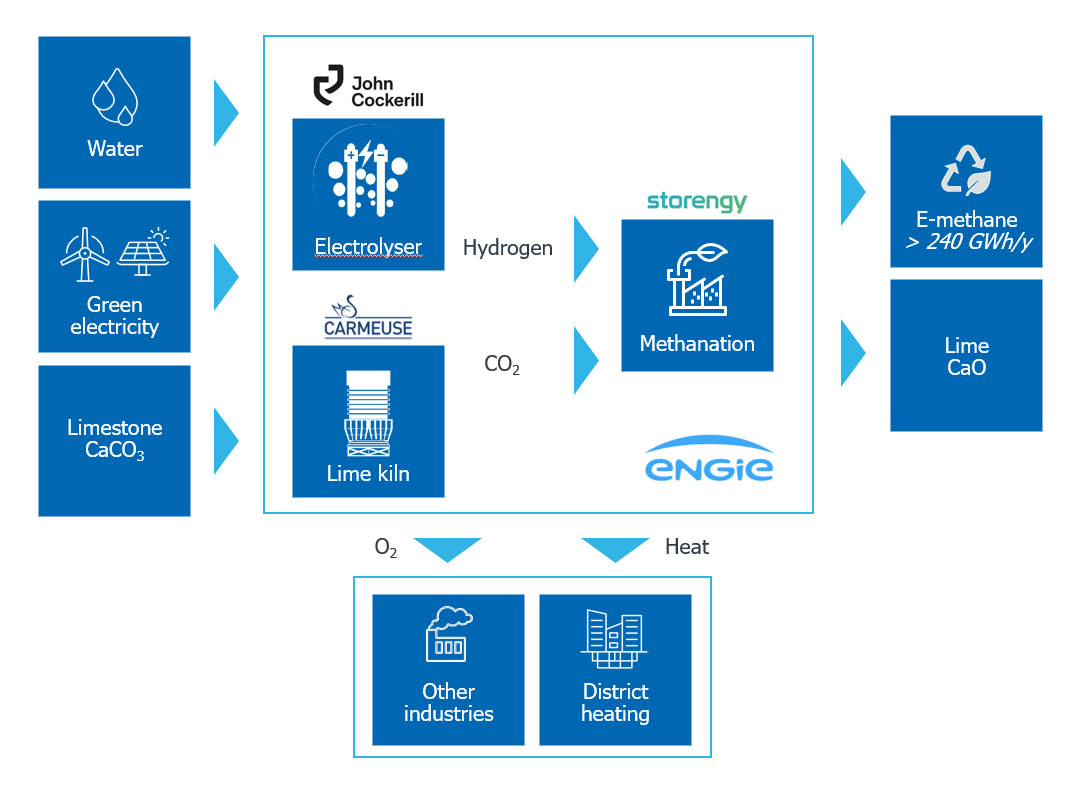

Carmeuse, ENGIE and John Cockerill have signed a Joint Development Agreement for an innovative Carbon Capture and Utilisation (“CCU”) project in Wallonia. This project will concentrate CO2 from an innovative type of lime kiln, combine it with green hydrogen and produce “e-methane”, a renewable gas that can be injected in the gas grid or used in transport or in the industry. The green hydrogen will be produced by a 75 MW electrolyser plant powered by green electricity. This project is the largest of its kind in the world. It opens new routes for significant carbon emission reductions in Europe and the world.

The project targets carbon emission reductions by using the CO2 generated during the lime production process into e-methane (methanation). The project will demonstrate at industrial scale a first-of-a-kind integrated process by up-scaling and combining available and prototype technologies, such as a new type of lime kiln, one of the world’s largest electrolysers (75 MW) and green hydrogen.

The produced e-methane will be high-quality, suitable for injection into the national natural gas grid. This renewable e-methane can be used by industrial users or as an alternative fuel in the transport sector, thus allowing these sectors to decarbonize.

To achieve this, three large industrial players have joined forces to further develop the project:

- Carmeuse will be responsible for the construction, commissioning and operation the new type of lime kiln, which allows for a concentrated CO2 stream.

- John Cockerill will be responsible for the design, engineering, construction and commissioning of a large electrolyser plant (75 MW) at an ENGIE site in the region of Charleroi, with key elements manufactured by John Cockerill.

- ENGIE will own and operate the electrolyser plant that will produce the green hydrogen. Storengy, ENGIE’s affiliate, will be in charge of the construction and operation of the methanation process.

The implementation of this project would make it possible to avoid more than 900,000 tons of CO2 emissions during the first 10 years. Moreover, it could enable future projects at larger scale in the lime-sector and replication in other CO2 intensive industrial sectors. It could turn Wallonia and Belgium into a world leader in CCU-based renewable energy carrier technologies.

The total investment cost for the project is over 150 million Euro. An application file for funding within the framework of the EU Innovation Fund and IPCEI (Important Project of Common European Interest) has been submitted and, subject to a successful outcome, the project implementation would start in 2022 to be operational in 2025.

Using CO2 emissions in the lime production process to decarbonize other industrial sectors

Lime is a widely used material in the production of common building materials such as bricks and mortar, as well as a chemical feedstock for a variety of other processes including steel production and sugar refining.

The chemical process of lime production generates CO2 emissions which cannot be avoided by the use of renewable energies. Carmeuse is developing an innovative process that will allow the production of lime with a concentrated CO2 stream, combining both the combustion related CO2 and the process CO2 that is released during the transformation of limestone into lime.

ENGIE will use renewable energy production capacity to feed a 75 MW electrolyser built by John Cockerill to produce green hydrogen. Storengy will operate the biomethanation plant which will combine the green hydrogen with the concentrated CO2 to produce e-methane. This biological methanation will be implemented thanks to Electrochaea’s technology. As the e-methane will be considered as a renewable fuel, the project contributes to the transition towards carbon neutrality of the final user of the e-methane.

Rodolphe Collinet, group CEO of Carmeuse: “We are delighted to join forces with John Cockerill and ENGIE for the development of this very exciting and strategic project. It is a major step forward in our ambition to become CO2 neutral by 2050. This project is a very concrete and important example of Carmeuse’s strong commitment and contribution to Sustainable Development. ”

Jean-Luc Maurange, CEO of John Cockerill: “John Cockerill is delighted to be partnering with two major players such as Engie and Carmeuse on this project that is strategic both, for our region and our planet. Thanks to our position as a world leader in the manufacture of large-capacity electrolysers and our anchoring in the heart of Europe, we are ideally positioned to make this project an innovative and emblematic success in decarbonizing the industry.”

Philippe Van Troeye, CEO of ENGIE Benelux: “We are proud to be part of to this promising joint project with Carmeuse and John Cockerill, that is fully in line with ENGIE’s ambition to be an accelerator of the energy transition. Thanks to its expertise, available sites and assets, ENGIE can produce and supply locally green hydrogen that will contribute to the circular economy of CO2 and lead to carbon neutrality.”

Visualization of the process

More details on the different partners of the project

Carmeuse

Founded in 1860, Carmeuse is a global manufacturer of lime, limestone and mineral-based products used in a variety of industrial, construction, soil improvement applications, and benefits the environment by providing cleaner air and safer water. Carmeuse and its subsidiaries also offer equipment and services to optimize its customers’ processes, improve safety, and provide reliable supply.

With headquarters located in Louvain-la-Neuve (Belgium), Carmeuse has approximately 4,500 employees and serves over 8,500 customers annually through a global network of 80 plants and 50 limestone quarries. Turnover in 2019 was €1.4 billion.

Carmeuse has long been concerned by its Greenhouse Gas emissions and aims actively at developing new technologies to reduce, capture and reuse CO2 emissions.

John Cockerill

John Cockerill Energy is a global player in the energy transition. For over 200 years we have been developing large-scale power generation solutions, including heat recovery steam generators. Aware of the challenges posed by global warming, we have been putting our expertise at the service of renewable energies for more than 15 years. As designers of the thermo-solar receivers for the largest concentrating solar power plants, pioneers in battery energy storage solutions with Europe’s largest industrial pilot plant (MiRIS), we are also a market leader in hydrogen. Our electrolysers, with the largest capacities in the world (from 5 to 1000 Nm3/h), meet the growing needs of the industrial, mobility, and, of course, energy markets.

With nearly 6,000 employees worldwide, the John Cockerill Group achieved a turnover of 1.26 billion euros in 2019 in 22 countries on 5 continents.

ENGIE

ENGIE is the Belgian market leader in the generation of electricity and the sales of electricity, natural gas and energy services. As the company has decidedly chosen the path of carbon neutral transition, it offers innovative solutions to its residential, professional and industrial customers, for a more economical and rational use of energy and greater comfort. As the country’s largest producer of green energy, ENGIE produces electricity close to its customers, through a diversified and low carbon production park.

Storengy

Storengy, an ENGIE subsidiary, is one of the world leaders in underground natural gas storage. Drawing on 60 years of experience, Storengy designs, develops and operates storage facilities and offers its customers innovative products. The company owns 21 natural gas storage sites with a total capacity of 136 TWh in France, Germany and the United Kingdom. Storengy is positioned today as a key player in the development of geothermal energy (heat/cold production and power generation), as well as innovative production and storage solutions for renewable gas (biomethane, hydrogen, synthetic methane).