Pioneer of the energy transition

Carmeuse, John Cockerill and ENGIE have signed a cooperation agreement to develop an innovative Carbon Capture and Utilisation (“CCU”) project in Wallonia, named Columbus.

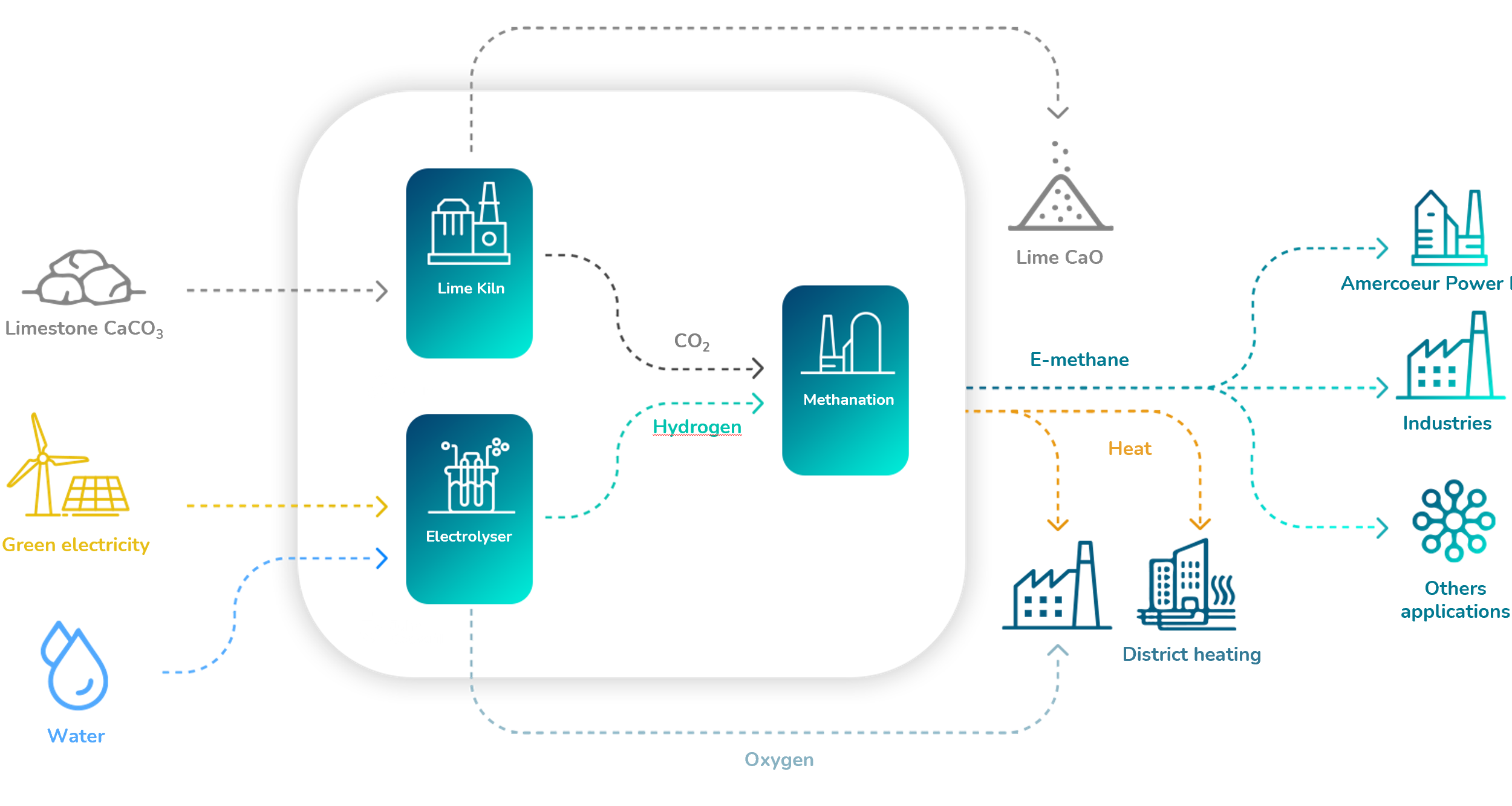

This project will concentrate CO₂ from an innovative type of lime kiln, and combine it with green hydrogen to produce synthetic methane, a renewable gas that can be injected into the gas grid or used in the transport or industry sectors. The green hydrogen will be produced by a 100 MW electrolysis unit, powered by renewable electricity. This project is one of the largest of its kind in the world. It opens the door for a significant reduction of carbon emissions in Europe and the world.

Our goals

Lime is a widely used material in the production of common building materials such as bricks and mortar, as well as a chemical feedstock for a variety of other processes including steel production and sugar refining. The chemical process of lime production generates CO₂ emissions which cannot be avoided by the use of renewable energies.

The project aims to reduce these carbon dioxide emissions by using the CO₂ released during the lime production process into e-methane (methanation). This project will demonstrate at industrial scale a first-of-a-kind integrated process by up-scaling and combining available and prototype technologies, such as a new type of lime kiln, a large electrolyser (100 MW) producing and green hydrogen and a methanation system. The e-methane produced will be high quality and suitable for injection into the national natural gas grid. This renewable e-methane can be used by industrial users or as an alternative fuel in the transport sector, allowing them to decarbonize. It doesn’t require any transformation in the customer’s processes or infrastructure as it has the same characteristics as natural gas.

The project will valorize all the side-streams of the production process and will create a circular economy

- the oxygen and heat released of the production process of hydrogen will be valorized in industry and in a local heat network in Charleroi

- the water released in the methanation process will be used in the hydrogen production process.

To achieve this, the three major industrial playershave joined forces to develop the project :

ENGIE will be responsible for the construction and operation of the electrolyser plant that will produce green hydrogen, and will build, own and operate the balance of plants and the methanation plant.

Carmeuse will be responsible for the construction, commissioning and operation of a new type of lime kiln, which allows for a concentrated CO₂ stream combining both the combustion related CO₂ and the process CO₂ that is released during the transformation of limestone into lime.

John Cockerill will be responsible for the design, engineering and commissioning of a large electrolyser plant (100 MW) at an ENGIE site in the Charleroi region, with key elements manufactured by John Cockerill.

The implementation of this project would allow to avoid up to 160 kt of CO₂ emissions per year, taking into account emission savings by the use of surplus heat to feed a local district heating network, valorisation of oxygen and contribution to network balancing. Moreover, it could enable future projects on a larger scale in the lime sector and replication in other CO₂-intensive industrial sectors. It could make Wallonia and Belgium a world leader in CCU-based renewable energy carriers technologies.

The total investment cost for the project is over 300 million Euro. A funding application has been submitted to the EU Innovation Fund and IPCEI (Important Project of Common European Interest) and, subject to a successful outcome, the project implementation would start in 2023 to be operational in 2026.

Up to 160 kt /y of CO2emissions avoidance

300M€

investment

70kt/y

of lime produced

100MW

of electrolysers (c.12kt/y of green H2)

370GWh/y

of e-methane

How it works

Industrial partners

ENGIE is the Belgian market leader in the generation of electricity and the sales of electricity, natural gas and energy services.

As the company has decidedly chosen the path of carbon neutral transition, it offers innovative solutions to its residential, professional and industrial customers, for a more economical and rational use of energy and greater comfort. As the country’s largest producer of green energy, ENGIE produces electricity close to its customers, through a diversified and low carbon production park.

John Cockerill is a global player in the energy transition.

With more than 200 years of experience, it is developing innovative technological solutions that contribute to the decarbonization of human activities, whether to optimize the efficiency of natural gas power plants, to produce electricity from renewable energy sources or to store green electricity. It adapts each of its technologies (large-capacity hydrogen electrolyzers, heat recovery steam generators, industrial boilers, thermo-solar receivers, battery systems) to the specific needs of its energy and industrial customers. Thanks to its electrolyzers, with the largest capacities in the world (more than 1000 Nm3/h – 5MW), it meets the growing green hydrogen needs of the mobility, industrial and, of course, energy markets. John Cockerill is making its technological contribution to the fight against climate change. In 20210, John Cockerill had sales of 947 million, in 22 countries, on 5 continents. www.johncockerill.com

Founded in 1860, Carmeuse is a global manufacturer of lime, limestone and mineral-based products used in a variety of industrial, construction, soil improvement applications, and benefits the environment by providing cleaner air and safer water.

Carmeuse and its subsidiaries also offer equipment and services to optimize its customers’ processes, improve safety, and provide reliable supply. With headquarters located in Louvain-la-Neuve (Belgium), Carmeuse has approximately 4,500 employees and serves over 12,700 customers annually through a global network of 90 plants and 60 limestone quarries. Turnover in 2021 was €1.376 billion. Carmeuse has long been concerned by its Greenhouse Gas emissions and aims actively at developing new technologies to reduce, capture and reuse CO2 emissions.

News

ENGIE en Carmeuse kondigen de stopzetting van het Columbus-project aan om economische en reglementaire redenen

ENGIE en Carmeuse zijn genoodzaakt om het ‘Columbus’ project stop te zetten, een industriële installatie voor…

Columbus krijgt steun van het Europees Innovatiefonds

In het kader van de energietransitie heeft Europa verschillende steunmechanismen opgezet, die gericht zijn op de…

Columbus krijgt steun van IPCEI

Met het Columbus-project hebben Carmeuse, ENGIE en John Cockerill hun krachten gebundeld om de industriële CO2-uitstoot…

Contact-us

If you are interested in learning more about the Columbus project, please contact us here.

XS Custom est une marque déposée de la société e-CT Consult SPRL. Cookie policy et privacy policy.